Plastics processing

For more than 60 years, cetto PLASTICS has stood for innovations and developments in the fields of thermoplastics and thermoplastic elastomers (TPE), tool technology and the associated automation solutions.

Together with our sister company, cetto BOHEMIA sro, we are continuously expanding our experience in processing thermoplastics and high-temperature-resistant plastics through to research and development with biopolymers.

In the name of Industry 4.0, we are working with various universities on innovations and new solutions that connect plastics and other industries. Our goals are more adaptability, resource efficiency and the integration of customers and business partners into our business and value creation processes.

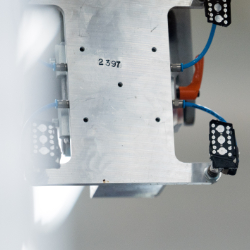

Hightech insert molding technology

We are experts in the concern of assemblies for cars, engines, or electronics and know how to perfectly realize the requirements of engineers and clients into products and deliver them just-in-time. For instance, components in the engine compartment are exposed to particularly mechanical, thermical, as well as chemical challenges. We solve the problems with high-temperature resistant, non-flammable materials or different fillers. The results are plastics parts and assemblies for better safety, performance, as well as improved comfort in the fields of automotive and electronics.

Multiple components technology

In the field of automotive electronic assemblies and their failure safety play a decisive role. For our clients we produce sophisticated mechatronic parts with all requirements after design, finishing, and modular structure (company logo concerning customer requirement). Requirements for 2K-parts vary from waterproofness up to scratch and break resistance. Mastering the multiple components technology is prerequisite to fulfill these requirements.

Overmold technology

Using appropriate material and their optimal processing, designing the parts according to insert molding, choosing and developing an appropriate insert molding tool and both in connection with the right simulation are requirements to be able to fulfill certain specifications. We possess particular production knowhow concerning overmolding metals. The combination of tooling knowhow, insert molding knowhow, as well as experience in the processing of thermoplastics and thermoplastic elastomersis the secret of our success.

Assembly

Integrated system solutions are created in automatic, semi-automatic or manual assembly lines. Our experienced employees at cetto PLASTICS and cetto BOHEMIA conscientiously assemble your assemblies and react quickly to changed requirements or new versions.

Connection technology

For the purpose of a rational production we use different connection technologies. Depending on the component we use ultrasonic welding, high-frequency welding, laser welding, as well as vibration welding or heating element welding. The results are ready to go into production systems and assemblies with excellent quality. Additionally, we use different adhesive technologies economically usable for all quantities.

Product refinement

Insert molding, electroplating, lasers and radiation crosslinking are some of our product refinement processes. Insert molding technology has been one of the highlights in our production portfolio for decades and is the basis for our market success.

Packaging

Perfection - also in respect of packaging and logistics. cetto PLASTICS supervises you worldwide in concern of the whole supply chain, starting with the development up to international logistics. The result are part specific assembly and packaging solutions. By request we develop complete automatization solutions for your production and fulfill your requirements concerning trays, blisters, or ESD-protection. Depending on the requirements we also pack in white or special lean rooms. Using returnable packaging is self-evident.