Product & process development

Our experienced project managers are at the cutting edge of science and continuously monitor the world market in terms of technology, quality, price and adherence to deadlines.

The wealth of knowledge that has been built up over decades through a large number of projects that have already been implemented is precisely applied, which ensures the satisfaction of our customers. We offer our customers worldwide professional product and process development under our own project management, which maps the entire production stages.

In order to ensure the best possible quality of our products, we also operate our own tool shop, which focuses on optimizing cycle time and quality and which goes hand in hand with our project management and production. The result is minimized distances between the production steps, which means that we guarantee our customers that deadlines are met and projects are implemented as quickly as possible.

Product developments

We develop products and ensure optimal and efficient processes in such that we make use of Simultaneous-Engineering. In so doing, we can avoid unnecessary time losses and assure product success and a rapid market launch. Simultaneous engineering is just one term in our close and trusting cooperation with our customers. You are accompanied by ONE contact person who is responsible for you and answers all your questions. Cooperations with other companies as well as universities and institutions make sure that the best knowledge and quality are used for your products.

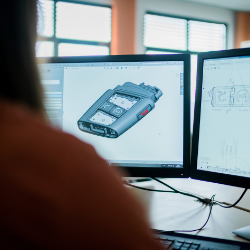

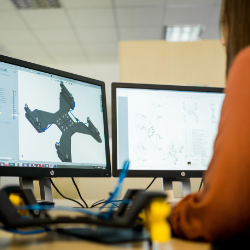

Design/Construction

With perfect component design to serial production. Due to a close cooperation already in the phase of idea finding and development, together we find the relevant savings potentials which significantly impact all further phases concerning costs and time optimizations. This means that cetto customers receive structurally optimized products and system solutions that have been tested for feasibility and are ready for series production. We already consult you in the beginning of the project in regard of design and optimized materials and we can elaborate cost optimized improvement potentials with simulation programs.

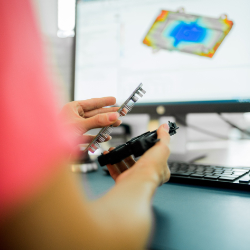

Simulations

cetto possesses the necessary practical knowledge with decades of experience with installing of insert molding machines, mold validation of first samples as well as process optimization. With the help of the simulation tool Moldflow we conduct filling simulations and cover the whole insert molding cycle. Apart from compact insert molding we can simulate all special procedures of insert molding, for example multiple component insert molding.

Rapid Prototyping

3D-Printing, stereolithographic, multi jet modeling, aluminium pre-series tools, steel pre-series tools are only some examples for tools we use to produce experimental tools or hand samples. Due to our tool acquisition in China we can also realize experimental tools quickly and effectively. Exorbitant short cycle times for tools Made in China even offer the opportunity to abdicate prototype or low volume production tools and to start right away with the serial tool in similar time periods.

Process development

Zero-defect quality from the first injection cycle. The consistent increase in quality performance is an essential part of our zero-defect strategy. Depending on the requirement profile, we equip our tools with various sensors for process control and process reliability. Extended visual inspection systems for particularly quality-critical features are used where tool technologies and monitoring options on the injection molding machine have their limits.

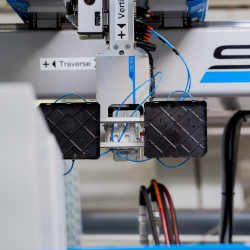

Automatization/Robotic

To be able to deliver the newest product generations safely, effectively and cost optimized, we use handlings and robotic systems. The production systems are adapted individually due to the customer product and developed from our staff - also in cooperation with external service contractors.

Tool technology

In order to be able to procure tools under optimized economic conditions, we have preferred suppliers in Germany, Portugal, the Czech Republic and China.

In every country we have experienced project managers on site who constantly monitor the market with regard to technology, quality, price and adherence to deadlines and who are very familiar with a large number of projects that have already been carried out. We offer our customers worldwide professional tool procurement under our own project management.

In order to ensure the best possible quality of our products, we also operate our own tool shop. The focus is on optimizing cycle times and quality.